|

||||||||||||

|

||||||||||||

| RO Unit Components: Basic Assembly | ||||||

| Page 2 of 7 | Pages: 1 . 2 . 3 . 4 . 5 . 6 . 7 | |||||

Photo 3: Next, the fittings are attached to the prefilters cannisters with a wrench. Straight fittings are used for the first feed connection and the last filter connection because they will be fitted with 180 degree rotatable fittings for ease of installation by the user.

Photo 3: Next, the fittings are attached to the prefilters cannisters with a wrench. Straight fittings are used for the first feed connection and the last filter connection because they will be fitted with 180 degree rotatable fittings for ease of installation by the user.

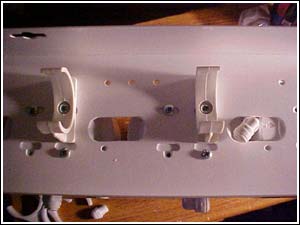

Photo 4: Next, a white powder coated steel bracket is screwed to the top of the canisters, providing stability to the canisters and support for the upper stages. Additionally, two membrane housing clips are attached.

Photo 4: Next, a white powder coated steel bracket is screwed to the top of the canisters, providing stability to the canisters and support for the upper stages. Additionally, two membrane housing clips are attached.

Photo 5: Here's a top view of the attachments. Note the angled fitting for the DI unit coming through a gap in the bracket. The screws being used are stainless or galvanized for protection from rust.

Photo 5: Here's a top view of the attachments. Note the angled fitting for the DI unit coming through a gap in the bracket. The screws being used are stainless or galvanized for protection from rust.

Next, the membrane. The most important and expensive part of the unit, the membrane provides filtering action down to the atomic level. Standard TFC (Thin Film Composite) membranes have holes that are between 200 and 400 atomic mass units (1 Neutron=1 AMU). These tiny holes allow water, H2O, to pass while trapping larger molecules on the surface of the membrane where they are washed away by waste water. more... |

|

|||||

| About Us :: Message Board :: Chat | |||||

| Library :: Photo Gallery :: Links & Resources :: Breeders & Sponsors :: Merchandise | |||||

| Website designed by: EthanCote.com | © 2001-2004, SimplyDiscus.com. All Rights Reserved. | ||||